Get optimum strength, flexibility and performance in a more environmentally friendly culvert pipe.

Corrugated Steel Pipe (CSP) from AIL is the material of choice for new or replacement culvert projects, reline projects and many other drainage applications.

A high-quality corrugated metal pipe that is built to last

AIL’s Corrugated Steel Pipe will not crack under impact loads or vibrations due to the inherent strength of steel and the flexibility of the corrugated pipe section. The high ring compression of the pipe absorbs and transfers the load to the surrounding soil around the entire circumference. The beam strength maintains the grade and line of the drainage pipe by bridging inequalities of the trench bottom and side fill.

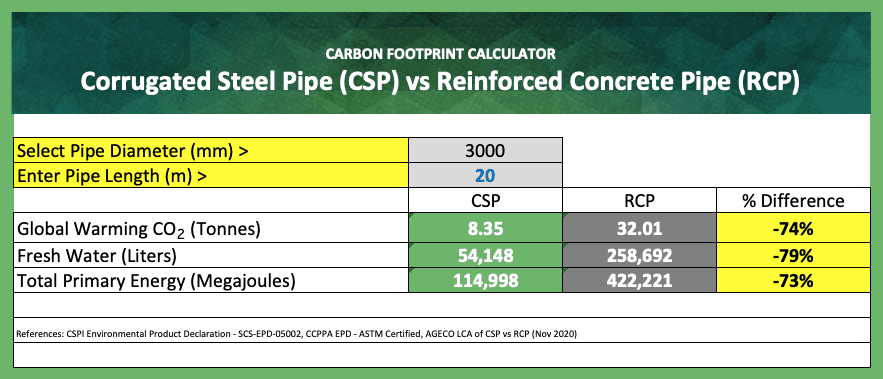

Corrugated Steel Pipe has a smaller carbon footprint than concrete*

In a 3,000 mm size, for example, Corrugated Steel Pipe’s carbon footprint is 74% smaller* than that of a Reinforced Concrete Pipe. In fact, Corrugated Steel Pipe delivers a wide range of environmental benefits including: reduced greenhouse gases, lower pollution, less acid rain and a reduction in depletion of materials such as the water and energy used in manufacturing.

Corrugated Steel Pipe vs Reinforced Concrete Pipe

Use the Carbon Footprint Calculator to see the difference. It’s easy!

Download the Carbon Footprint Calculator >>

AIL’s Corrugated Steel Pipe is inventoried in storage yards across Canada, ready to ship for emergency culvert washout replacements and other types of drainage projects.

Common corrugated metal pipe applications include culverts, drainage systems, stormwater management systems, fish passages, culvert relines, conveyor covers or overcasts and ventilation or utilidor systems.

Optional coatings

Providing a design service life of 25 to 100+ years, AIL offers three factory-applied finishes to meet your performance and hydrology considerations on your drainage project. Soil conditions and a variety of other site/application factors can influence your choice of Corrugated Steel Pipe coatings. An environmental assessment will help you select the appropriate coating to meet your site’s requirements.

- Galvanized – Standard service life of 25 years

Galvanized Coating is the standard finish for all Corrugated Steel Pipe and performs well in low-abrasion conditions. - Aluminized Type 2 – Service life of 75 years

For more corrosive environments, Aluminized Type 2 coating offers the superior corrosion resistance and surface characteristics of aluminum with the strength and economy of steel. - Polymer-Laminated – Service life of 100+ years

Polymer-Laminated Coating is a tough, heavy-gauge film that is laminated on both sides of galvanized steel to produce a corrosion and abrasion barrier that will stand up to high concentrations of acids and alkalis in the most aggressive environments.

*CSPI Environmental Product Declaration – SCS-EPD-05002, CCPPA EPD – ASTM Certified, AGECO LCA of CSP vs RCP (Nov 2020)

BROCHURES & VIDEOS

-

Corrugated Steel Pipe Brochure

6-page, full-colour brochure outlining CSP product including applications and specifications.

Download(11.83 MB)

-

Corrugated Steel Pipe vs Reinforced Concrete Pipe - Carbon Footprint Calculator

Corrugated Steel Pipe vs Reinforced Concrete Pipe. Which is “greener?” Use the Carbon Footprint Calculator to see the difference. It’s easy!

Download(178.80 KB)

RELATED PRODUCTS

-

Corrugated Aluminum Pipe

Chosen for superior corrosion/abrasion resistance in harsh drainage environments..

-

Hi-Flo Smoothwall Spiral Rib Pipe

Solve your stormwater challenges with the improved hydraulics of Hi-Flo.

-

STORMAWAY Stormwater Management Systems

Economical stormwater detention or stormwater retention systems.