Lightweight, versatile shaft form liner

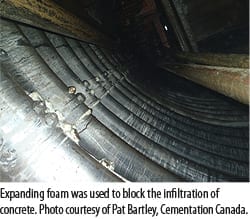

Cementation Canada Inc. was contracted by New Gold Inc. to line a 3.6 m diameter vertical shaft at their New Afton Mine near Kamloops, BC. The liner was to begin at 150 m below the surface and extend downward for another 150 m, acting as a “stay-in-place” form liner for concrete placed against the rock face.

Cementation contacted AIL Mining to develop a suitable solution. A Dur-A-Span Structural Aluminum Plate design was selected for its light weight and versatility.

Pressures on this liner would be limited to the concrete pressure — in fact, no soil pressure was considered and the liner would only act as form/false work. AIL Mining confirmed that pressure loads acting on form/false work would be best determined by Cementation, given they would have a better sense of the concrete pressure, density, lift heights and overall construction method.

To initiate the design process, AIL Mining sent the section properties for Dur-A-Span corrugated aluminum structural plate (230 mm x 64 mm) to Cementation for review. Cementation selected a 3.354 m ID (3.481 m OD) Round Dur-A-Span Structure with 3.175 m wall thickness plate, measuring 150.88 m in length.

Patch plates, 723 mm x 488 mm, were also fabricated and curved. These were used to place patches over the concrete injection holes that were to be field drilled through the plate.

“Your product is lightweight, easy to handle in tight work areas and conforms easily to changing conditions. I have no issue recommending these formed aluminum rings for raise rehab work and concrete retention (forming) in a mining environment.”

—Pat Bartley, Project Manager, Cementation Canada Inc.

Shop drawings indicated circumferential seams were staggered 686 mm to avoid four plate laps. Fasteners to assemble the structure were standard 19 mm diameter galvanized bolts — 32 mm and 50 mm in length.

Following shop drawing approval, the Dur-A-Span liner was fabricated and shipped to the site in two to three weeks. Approximately four weeks later, an AIL Mining Field Engineer visited the site and went down the shaft to review the installation progress and to offer assistance.

Field notes:

- The aluminum sheets were lightweight and easy to field fabricate in a mineshaft.

- The original plate layout with the staggered seams was changed to have a circumferential seam every 1.372 m in elevation.

- Transverse seam boltholes were relatively easy to align and the standard 19 mm diameter bolts were used.

- Circumferential seams were connected with self-tapping screws approximately 0.3 m on centre. This was found to be much easier than trying to align the circumferential holes and insert the 19 mm diameter bolts.

- Temporary steel pipe shores were installed at the circumferential seams during the concrete installation process.