AIL received a late request on Calgary’s Southeast Stoney Trail (SEST) ring road project to design and supply a structure-mounted AIL Sound Wall for one of their 32 recently constructed MSE Retaining Walls. A solution was needed that would not adjust the wall or change its design.

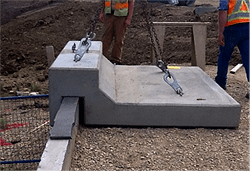

Precast momentum slab caps and coping installed in 1.5 days

Our engineering department’s solution using precast momentum slab caps and coping spacers fit the bill perfectly. The momentum slab caps with integrated mounting mechanisms resist wind loads and spread the weight, eliminating the need to rework MSE wall panels and mats or drive pilings.

Once the bed grade was prepared, the levelling pads, precast momentum slab caps and coping spacers were installed over the first day and a half with a three-person crew, a dozer and a zoom boom.

Sound barrier wall installs in just 6 hours

Once the precast elements were in place, a foreman and two labourers installed the sound wall in just six hours. A pathway was later poured over the momentum slab caps to match the road grade and curb.

Durable, lightweight AIL Sound Walls = lower installed costs

Made from recycled and recyclable PVC, AIL Sound Walls are easy to install with minimal equipment and labour requirements. They provide unmatched value and performance benefits, while delivering maximum mitigation of environmental or ambient sound such as traffic, manufacturing, industrial or commercial noise. Our turn-key solutions include: engineering, manufacturing, project management and site assistance.