March 11, 2024

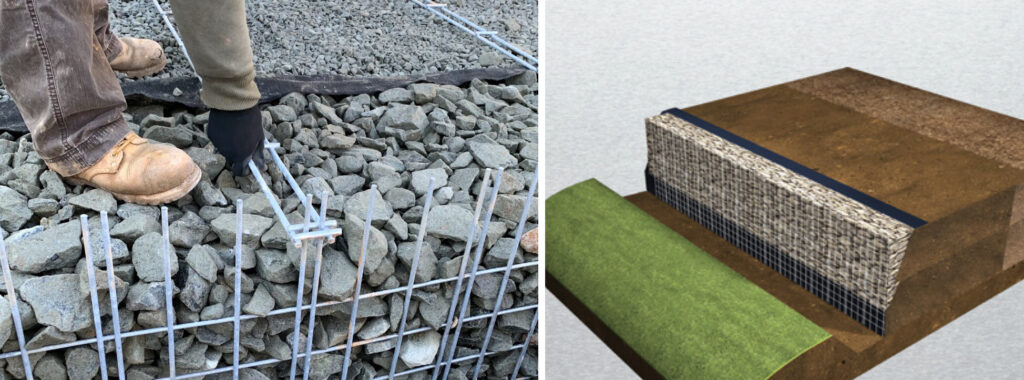

This smaller-scale MSE Wire Wall project shows the versatility of our MSE Wire Walls with the Track-Strip Soil Reinforcement System. Wire Walls easily accommodate curves, angles or steps as they adapt quickly to culverts, bridge piles or other site anomalies.

Track-Strips make the retaining walls easier to design, store on-site and construct

In this case, our face panels were adapted to accommodate two drainage culverts and the Track-Strips were easily angled to skew around the guide rail posts.

MSE retaining wall project meets tight timeline with “One Team” approach

This project also demonstrated the true power of AIL’s “One Team” approach. The contractor, St-Isidore Asphalte, had a very tight timeline which we were able to meet thanks to everyone pulling together and great communication between project partners.

Retaining wall materials on-site one month from order date

St-Isidore issued our PO on September 15 and needed all components on-site within one month. Everyone came together when it didn’t seem possible to meet the deadline. Excellent communication and record-keeping helped us ensure a successful outcome. We leveraged our engineering team to have the IFA drawings expedited and we provided weekly updates to our project partners. St-Isidore was pleased with the project outcome and gave us two drainage pipe orders, to boot!

A resilient and sustainable retaining wall solution

Our MSE Wire Walls are very flexible and offer excellent settlement ranges. And, because they are made from steel instead of concrete, they are considered a greener alternative. Plus, they usually use locally available materials for their engineered backfill and cobblestone face.